Home / Fuel Cell compressors

PRODUCTS

Fuel Cell Compressors

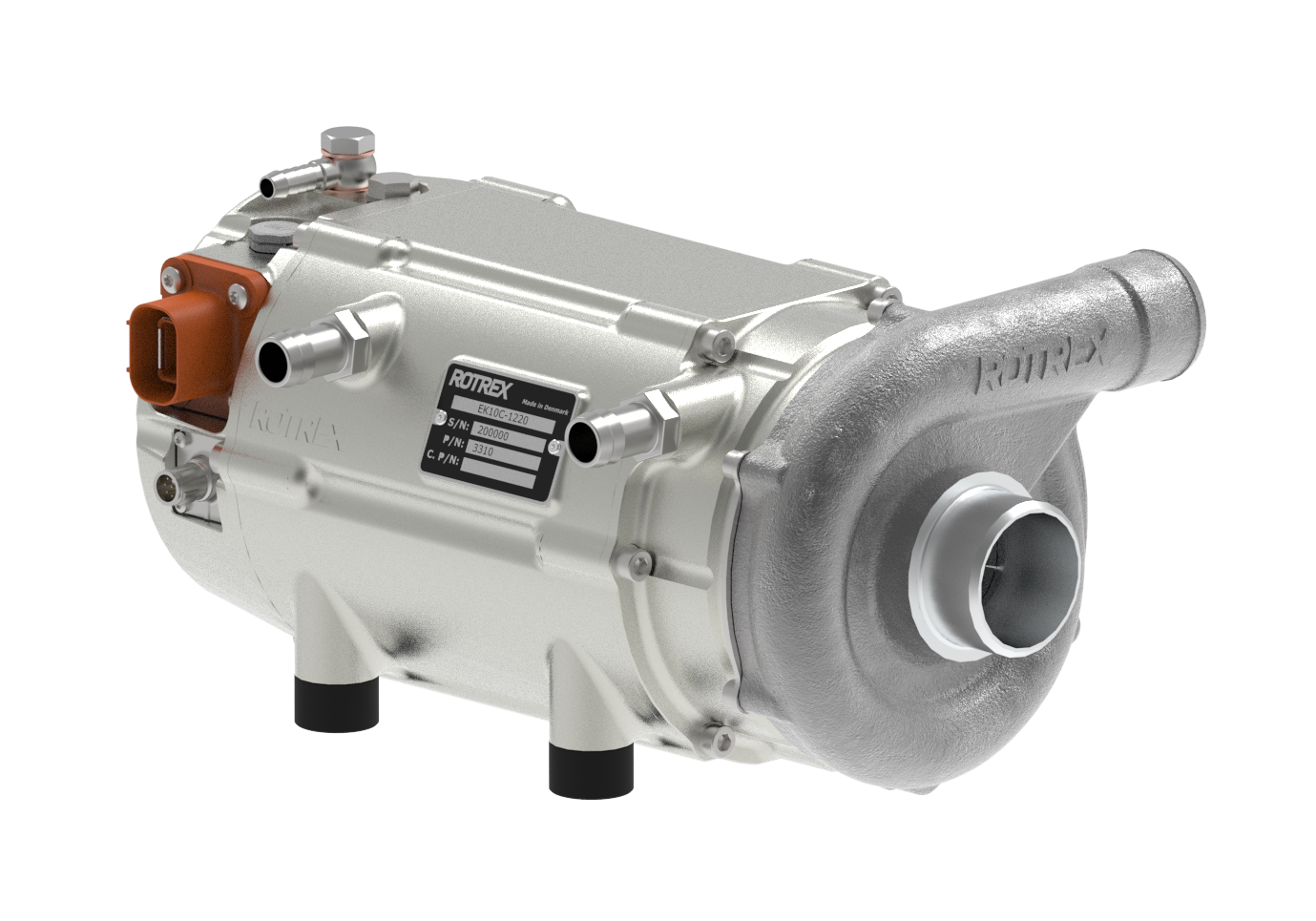

EK-Series

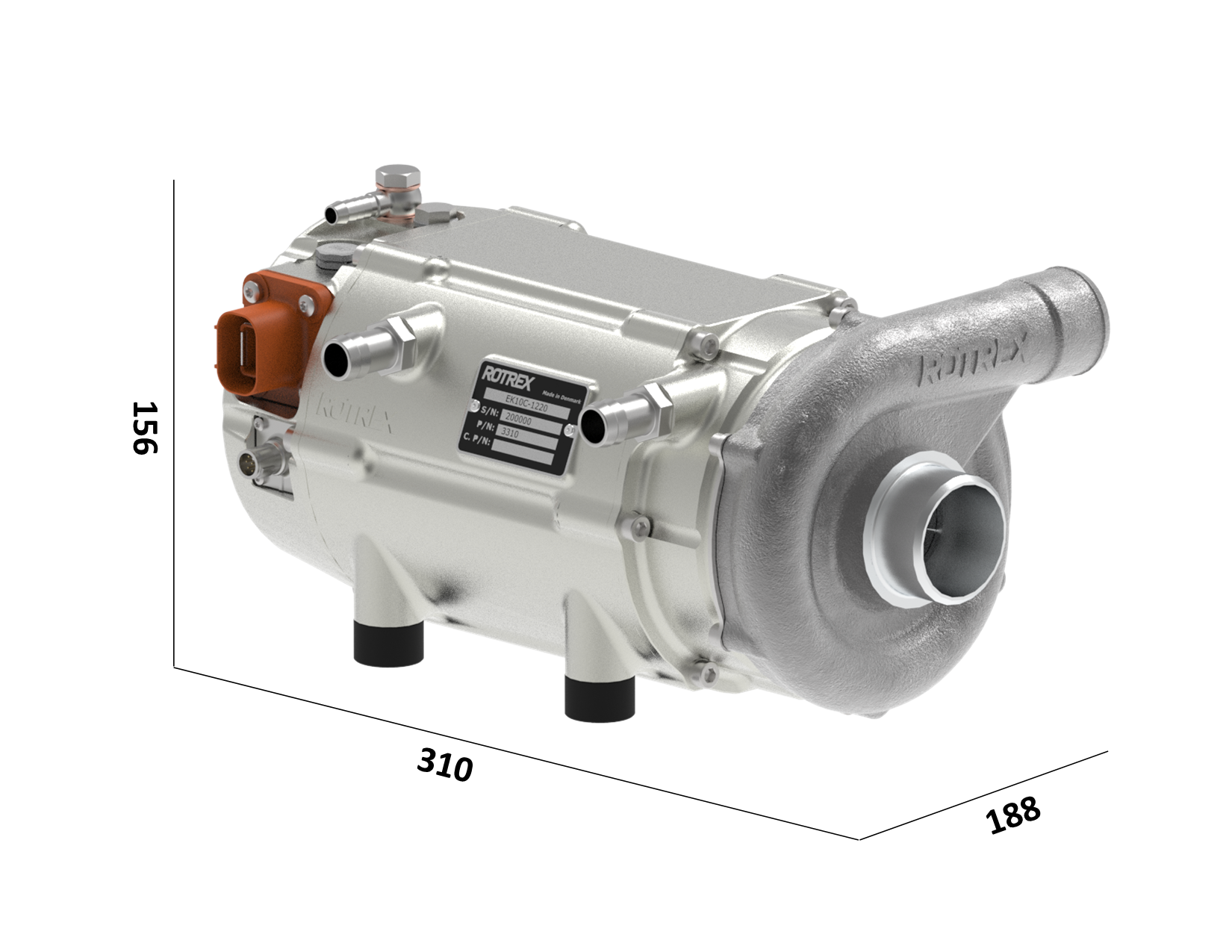

The EK series is our most compact electrical compressors. These units are fully integrated units with a built-in liquid cooled motor, traction drive and lubrication. A suitable motor controller is supplied with the unit. The only external requirement is a liquid coolant system.

Aviation

Stationary

Maritime

Trucks

Heavy duty

Busses

Railroad

Automotive

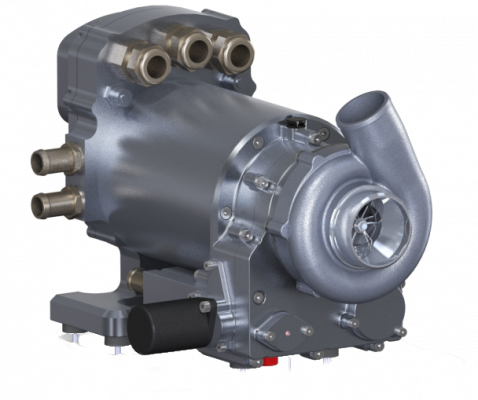

EC-Series

The EC series are modular systems, ideal for stationary applications like fuel cell test equipment and proof of concept etc. Rotrex offers a wide range of standard configurations consisting of a C-type supercharger combined with an e-motor. An oil reservoir and heat exchanger is supplied with the unit along with a suitable motor controller. Whenever a steady, non-pulsing air supply is needed, Rotrex has a solution ready.

EC15

17kW fuel cell compressor unit suitable as lab-test air supply for fuel cell stacks of 75-100kW

EC30

35kW fuel cell compressor unit suitable as lab-test air supply for fuel cell stacks of 120-300kW.

EC38

59kW fuel cell compressor unit suitable as lab-test air supply for fuel cell stacks of 180-500kW

| Characteristic | EK10 | EK40 |

| Suitable fuel cell power range | 20 – 100 kW | 100 – 400 kW |

| Recommended air mass flow range | 0,025 – 0,080 kg/s | 0,1-0,3 kg/s |

| Recommended pressure ratio range | 1,4 – 2,2 | 1,4 – 2,8 |

| Acceleration rate (T90) | <2 sec | <2 sec |

| Dimensions (mm) | 321 x 155 x 188 | 450 x 250 x 220 |

| Weight (operational) | ≈ 13 kg | ≈ 30 kg |

| Internal drive ratio | 1 : 8.44 | 1 : 7.5 |

| Maximum motor shaft speed | 16.600 RPM | 16.000 RPM |

| Maximum impeller speed | 140.000 RPM | 120.000 RPM |

| Rated motor power | 13 kW | 40 kW |

| Rated supply Voltage | 200-800 VDC** | 200-800 VDC** |

| Enclosure rating | IP67 Accredited | IP67 minimum |

| Characteristic | EC15 | EC30 | EC38 |

| Suitable fuel cell power range | 75 – 200kW | 120 – 300 kW | 180 – 500kW |

| Recommended air mass flow range | 0,08 – 0,22 kg/s | 0,12 – 0,36 kg/s | 0,12 – 0,55 kg/s |

| Recommended pressure ratio range | 1,4 – 2,4 | 1,4 – 2,6 | 1,4 – 2,6 |

| Acceleration rate (T90) | <2 sec | <2 sec | <2 sec |

| Physical dimensions (LxHxW in mm) | 350 x 250 x280 | 545 x 260 x 270 (max) | 545 x 260 x 270 |

| Weight (operational) | ≈ 16 kg | ≈ 18/38 kg | ≈ 39 kg |

| Internal drive ratio | 1 : 12,67 | 1 : 9,5 | 1 : 7,5 |

| Maximum motor shaft speed | 17.500 RPM | 12.650 RPM | 12.650 RPM |

| Maximum impeller speed | 216.000 RPM | 120.000 RPM | 90.000 RPM |

| Rated motor power | 17 kW | 17/59 kW | 59 kW |

| Rated supply voltage | 470-800 VDC OR ~400 VAC** | 470-800 VDC OR ~400 VAC** | 470-800 VDC OR ~400 VAC** |

| Enclosure rating | IP67 minimum | IP67 minimum | IP67 minimum |

** The maximum available speed is highly dependant on the supply voltage.

Compressor maps

All compressor maps are verified in-house with our SAE flow rig.

Custom-made Fuel Cell Compressors

Besides our standard compressors, we also have the ability to develop custom-made compressors to suit your specific demands. Development includes tailored compressor geometry design, to optimize performance and efficiency for your application.

Contact us if you are interested in more information about this possibility.

About Fuel Cell Compressors

Rotrex was pioneering the development of compressors for the cathode air supply in fuel cell systems.

More than a decade of close cooperation with some of largest fuel cell companies has resulted in class leading and cost effective compressor solutions.

The first systems were introduced to the market more than 10 years ago and since then Rotrex fuel cell compressors are used globally in many type of industries.

All critical components are produced in Denmark in our state of the art facilities, where assembly, testing and final quality inspections also takes place.

Key benefits of our traction drive design

The compressors are based on our patented high speed traction drive, which is spinning a high efficient centrifugal compressor. The result is a class leading air compressor, that offers unmatched reliability.

- Clean Oil-free, linear and non-pulsing air supply

- Ultra-compact, lightweight and flexible integration

- Automotive design – high resistance to shock/impacts

- Class-leading efficiency

- Unmatched reliability

- Cost effective solution

EK10 fuel cell compressor

The EK10 is a unique fuel cell compressor combining the best of both worlds. It includes our proven traction drive to achieve unmatched impeller speeds (continuously), connected to a robust low-speed 13kW PMSM motor. The integrated lubrication circuit ensures ideal conditions for rotating elements, resulting in outstanding lifetime properties.

The EK10 is available in multiple configurations:

- 0822 air trim for high pressure applications

- 1220 air trim for high flow applications

- Multiple motor controller options are available (mobile or industrial type)

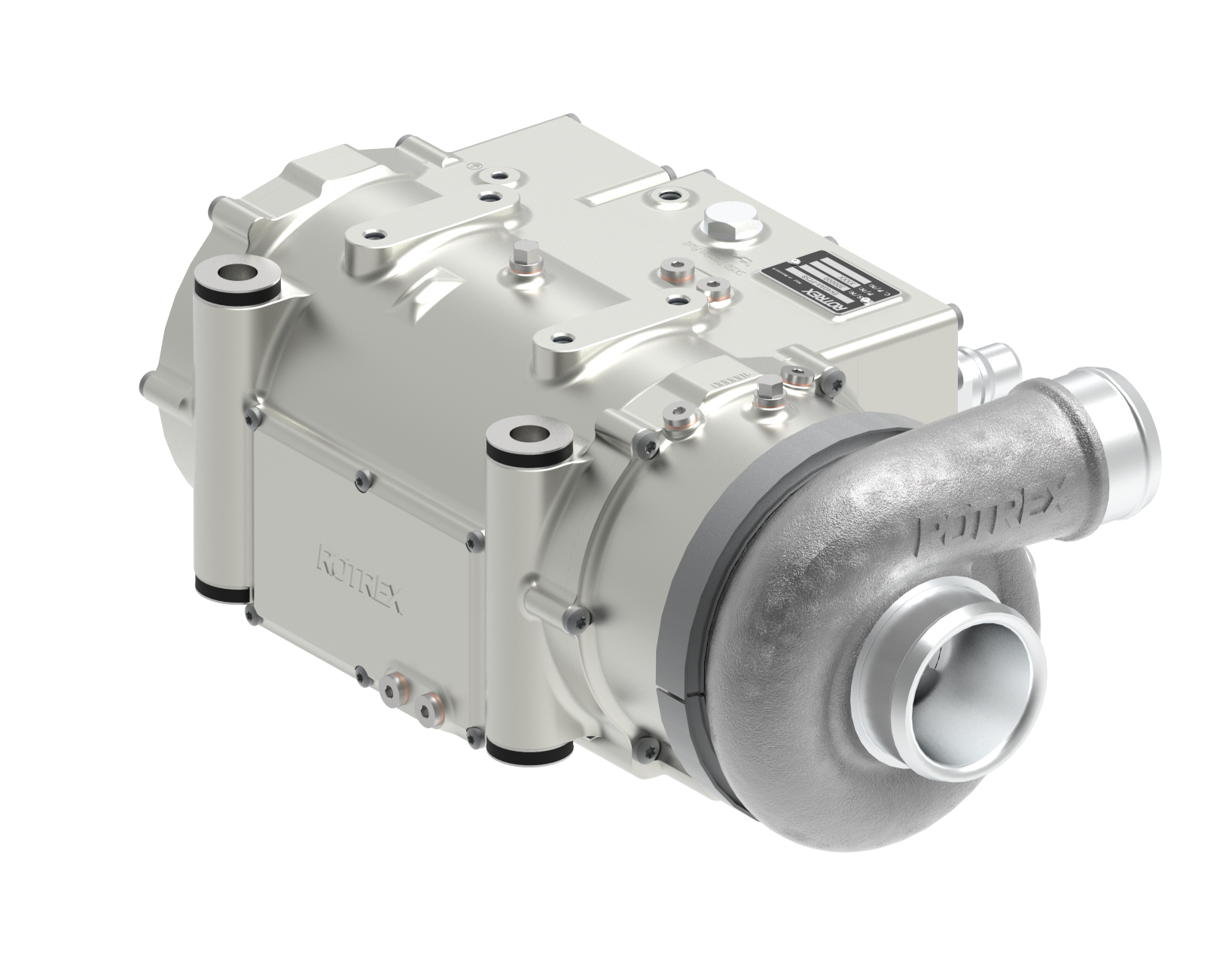

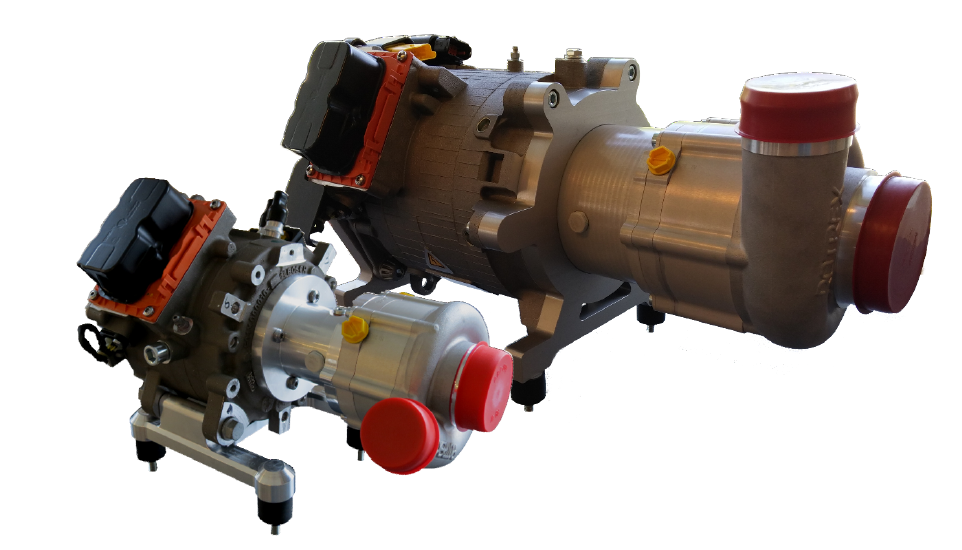

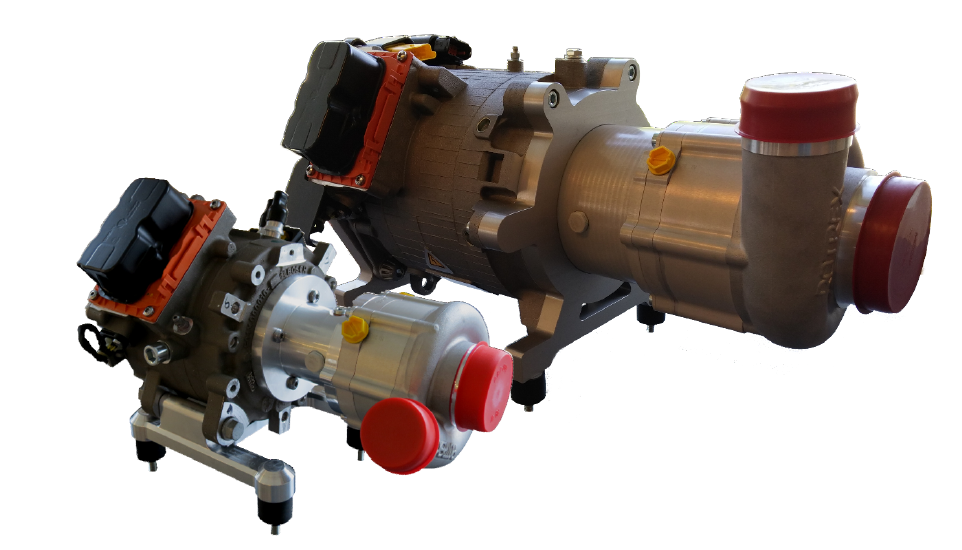

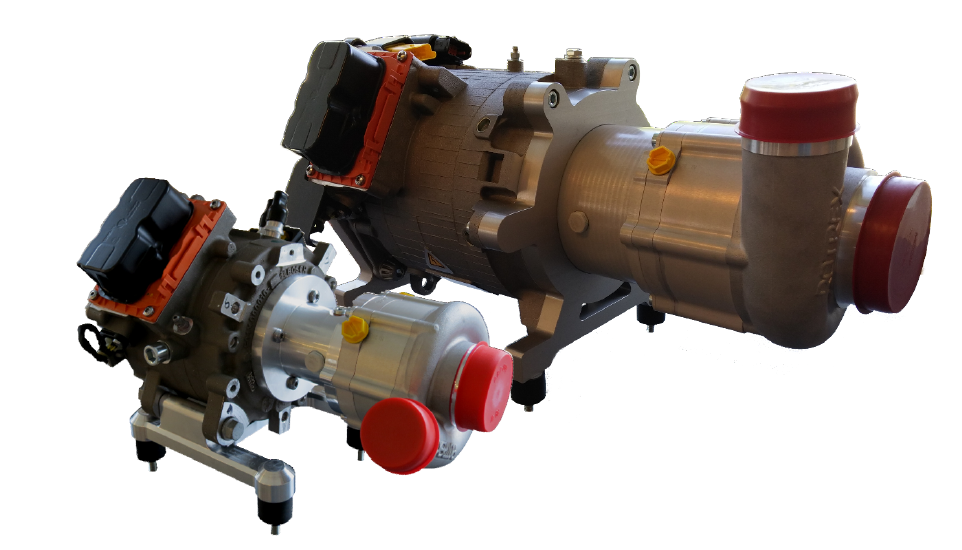

EK40 fuel cell compressor

The Rotrex EK40 is the most powerful fuel cell compressor on the market, designed specifically for heavy-duty applications and high power fuel cell stacks. With its capacity, it can support fuel cell applications up to 400kW.

The e-motor is an integrated, low-speed PMSM, with outstanding durability and resistance towards shock/vibrations along with excellent start-stop properties.

A unique feature of the EK40 is its modular setup, allowing for different configurations to suit each project. Modular design to enables:

- Single stage, high flow – high pressure

- Dual stage, medium flow, ultra-high pressure

- Single stage + turbine for recuperation

- Multiple air trims for multiple flow and pressure ratios