Why Rotrex is class leading

Rotrex is the inventor of the planetary traction drive and have been mass-producing the technology for the past +20 years. The traction drive is well proven, and is the key difference between our fuel cell air compressors and competing products on the market.

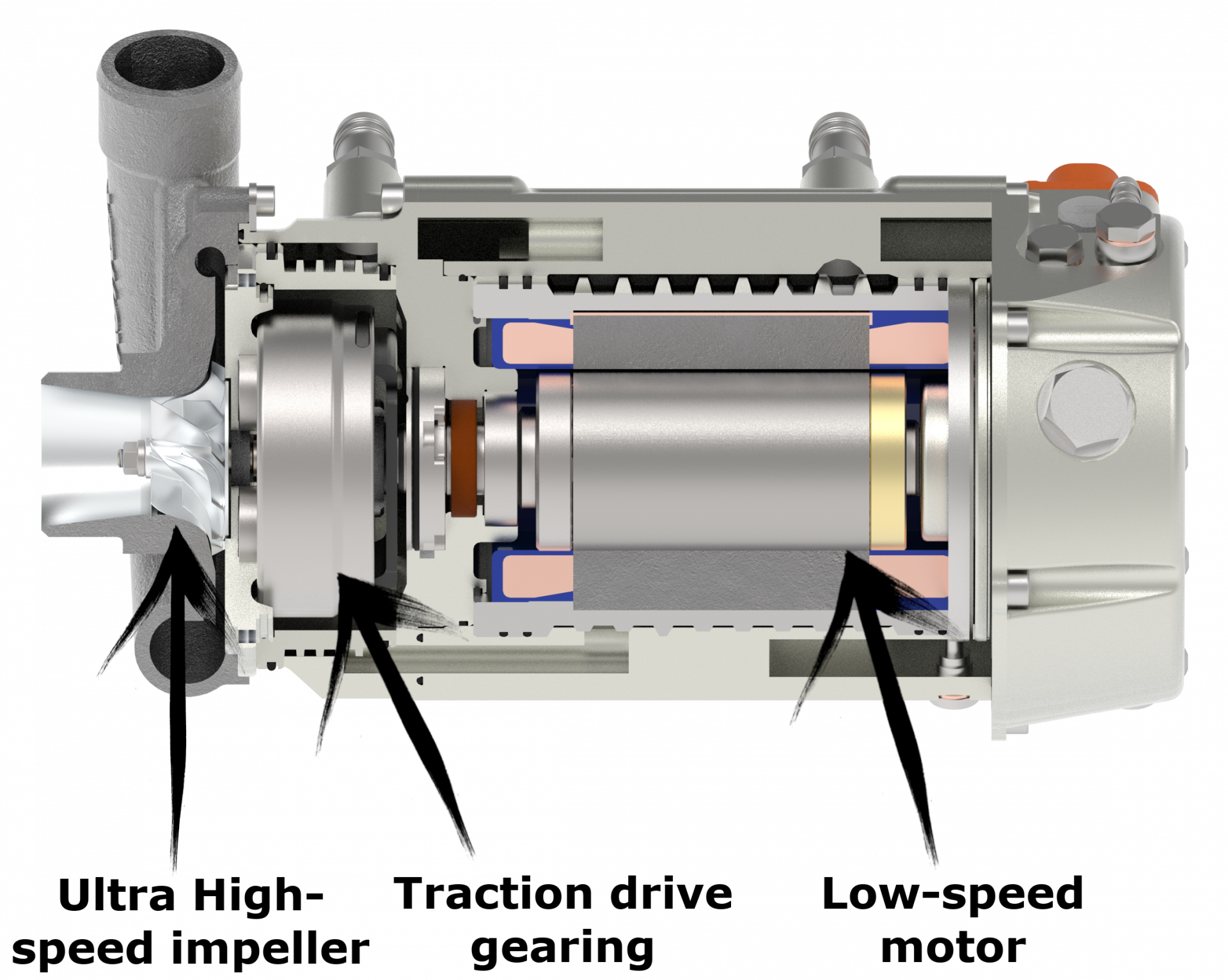

The most efficient centrifugal fuel cell air compressors creates pressurized air flow, by running an impeller at ultra high-speed. Competing products rely on expensive and sensitive ultra-high speed motors and bearings to run the impeller directly. Instead, we use our traction drive as step-up gear between the motor and impeller, enabling use of a low speed motor whilst achieving ultra-high impeller speed. This unique feature effectively makes our compressors more robust, efficient and scalable.

Drag the slider to see the unique design principle →

More Robust

Inherited from the automotive design, traction drive air compressors are profoundly robust and proven through numerous OEM projects. Using traction drive technology eliminates any sensitivity towards external shock/vibrations and air contaminants under use in even the most demanding environments.

More Efficient

Our traction drives typically runs up to 98% efficiency and can achieve up to 240.000 rpm of continuous operation. Therefore we are proud to show complete compressor maps, including efficiency islands. Under ideal use, our compressors can achieve a class leading 80% aerodynamic efficiency!

More Scalable

Our fuel cell air compressors are fully scalable to match any fuel cell application. We can offer tailored solutions beyond 200 kW of continuous compressor power. Because all development and manufacturing is performed in-house, we can also support tailored solutions for your project.

Besides the key benefits, our planetary traction drive compressors offers several more benefits such as instant response (T90 < 2s) and low NVH. Furthermore and very important we have optimized our production setup for the traction drive concept for more than 20 years and the result is a cost attractive solution, which is getting more and more important in the growing fuel cell market.

Please contact us if you want to know more about our advantages.

Technical walk-through

Select the icons to get more information about the unique features of our traction drive fuel cell air compressors.

Traction drive

The traction drive increases the speed from the motor to the compressor through a toothless planetary drive. The high speed output shaft runs completely bearing-less and can run at high speed for continuous operation. Typical drive efficiency is up to 98% depending on operation.

As the traction drive is toothless, no noise and vibrations is created, ensuring a silent, yet efficient operation.

Centrifugal compressor

With great speed comes great efficiency!

Centrifugal compressors is the most efficient compressor technology. And, because the traction drive can run at high speed, we can use the most efficient centrifugal compressor design. No low-specific-speed design prone to poor efficiency is needed.

All compressor design is created in house using specialised design software along with actual flow testing on our in-house SAE flow rigs. What you see is what you get.

Low-speed PMSM Motor

The main difference to our competitors is that we can use well-known low speed electronics. Running low speed with the motor means less sensitivity towards balancing, less centrifugal forces and less electrical inefficiency. Maximum motor speed is just 16.600 rpm.

Ball bearings

As the motor is spinning at maximum speed of just 16.600 rpm, we can use the most robust ball bearings on the market.

Ball bearings are great for reliability and insensitivity towards shocks and vibrations. Ideal for actual use in even the most demanding environments.